Sputtertalk

Join us as we explore the frontlines of innovation in experimental & applied engineering research. In each episode, we share insights from industry and academic professionals with experience working on real, impactful, projects. Listen to Sputtertalk for grounded conversations about building systems that matter.

Latest Podcast Episodes

Troubleshooting Your Magnetron Sputterer

Troubleshooting your Magnetron Sputterer

Like any normal nanofabrication engineer and reasonable person, you frequently access and use a magnetron sputterer as part of a nanocluster physical vapor deposition system. Alas, it's on the fritz! Low deposition rate, incredibly concerning noises emitted from the inside of your deposition chamber, random current fluctuations on your power source. You may be worried that you have somehow damaged an expensive and unique piece of equipment purchased by your lab 10+ years ago with little supporting documentation, and now you'll be loaded into the investigator-firing cannon and, well, fired. It's okay, your sputterer is just in need of some servicing.

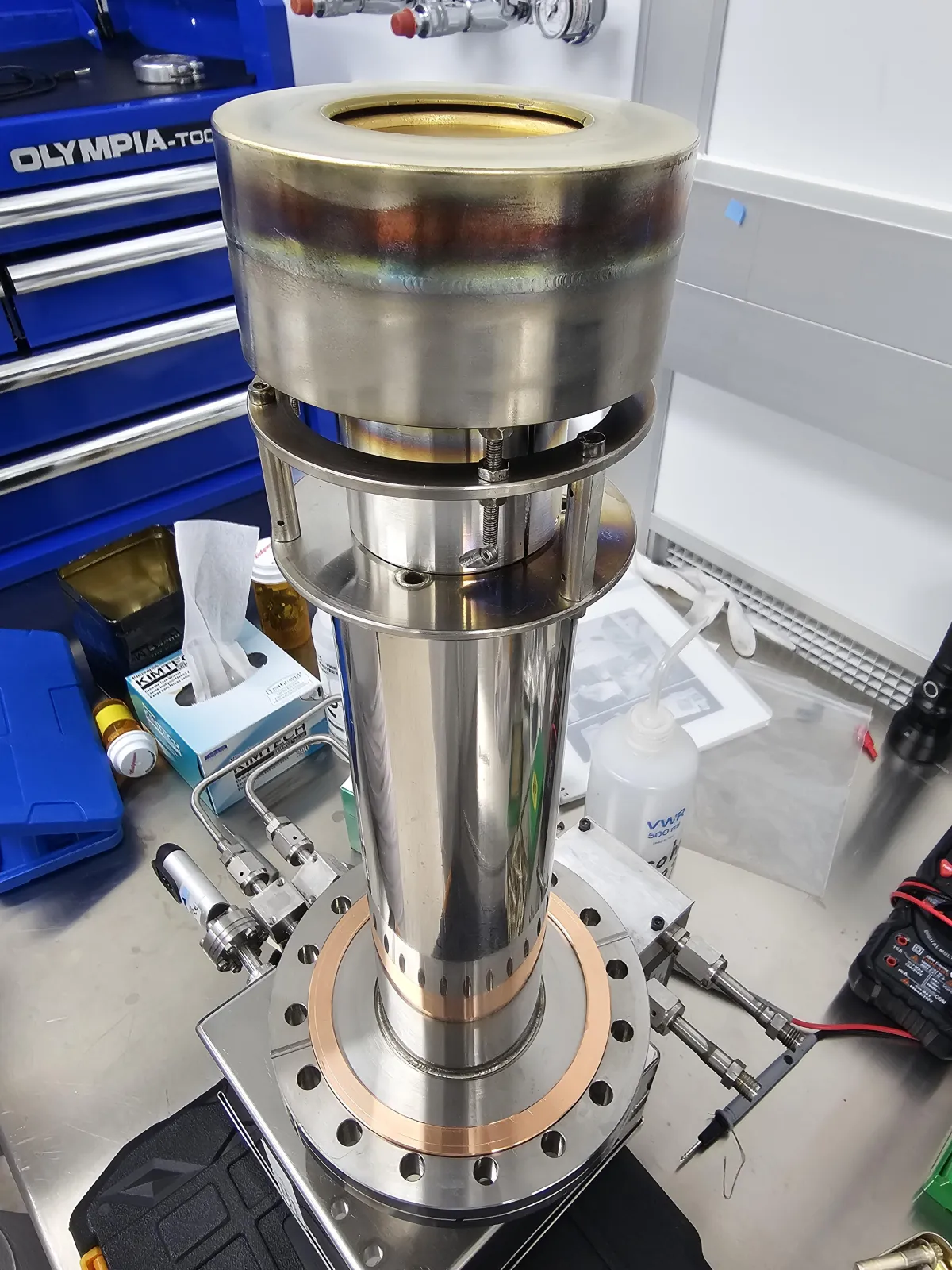

The most likely issue is target isolation. To generate a stable plasma, the gap between the target and the target holder must be (depending on your sputterer) in the range of 0.2-0.3 mm. This ensures enough isolation to facilitate the plasma generation, while not too much of a gap to inhibit it. If, using a thickness gauge, you measure the gap to be uniformly in your desired range, you have two other possible issues. Note, that with a nonconductive or semiconductive target, the gap must still be maintained, though the isolation might be harder to reliably measure. The target connects electrically to the rest of the sputterer, and any other point outside of the holder must also be isolated. Hopefully you have something more precise than a multimeter. State-of-the-art graphical representation of the aforementioned isolation in question:

That is the resistance between the target holder and the rest of the sputterer, noting that the target itself is conducting electrically to that tube during operation. In this occurrence, our resistance was 5 MΩ. Depending on our sputtering power, that'd be as much as 5-15% leakage, which is unacceptable.

If the target holder is properly seated, the issue might be the accumulation of flakes and particles from previous deposition runs underneath the holder. Remove the holder, which is usually done anyway when swapping targets, and carefully clean both it and the target area with an abrasive that won't release many particulates during use. My first time doing this cleaning, I dropped the target holder and absolutely warped the mounting screws attached to it. My more senior labmate spent maybe three

hours delicately rearranging them. That was a lesson in diligence and being intentional with my work that I will never forget. Don't be like me, and take care not to damage anything.

If the isolation still does not return, the issue is likely with the isolator that bridges the gap between the target holder and the rest of the sputterer. Different sputterers naturally have different procedures for getting access to this isolator, ours was pretty straightforward. Very fortunately and thankfully, we were able to reach out to the original manufacturer who still had the original documentation to fix this exact kind of issue. Thank you, Mike at Oxford Applied Research!

The process of disassembly is simple, but must be taken with great care. The target holder must be removed, followed by the target and any backplating/shielding, then the isolator shield, and any remaining materials in place to prevent accumulation on the isolator.

As you can see, our isolator was quite dirtied, and just enough accumulation is present to cause a significant amount of leakage to occur during sputtering. Being ceramic, and existing in an environment where every particle and type of particle must be precisely accounted for and controlled, we're limited in how we may clean this isolator. The original manufacturer recommends cleaning gently with an abrasive. Being in a cleanroom, naturally, any abrasive used should not be of a material that would release many particulates.

Clean the isolator and note the resistance now. It should be completely isolated, ideally. This fixed our isolation issue at the time, and we've conducted many successful experiments since having to service the sputterer. Across two years, we've needed to conduct this procedure twice.

I'd noticed occasionally we would still have isolation issues that were very intermittent, not repeatable by intention, and did not respond to isolator cleaning when present. The isolator should be the only determining factor beyond target holder cleanliness, but after further investigation, I noticed the argon gas tube (small tube left of the isolator in the previous image) is not electrically isolated from the main sputterer chassis, and particles also accumulate inside the slot where this tube sits inside the target holder. Cleaning this out with a small abrasive fixed this isolation issue.

If your magnetron sputterer is acting wacky and refusing to calm down, and nothing here worked nor are the original documentation or supplier able to help much, feel free to reach out to me and I may be able suggest something helpful.

Thanks for reading, and happy sputterer servicing.

Subscribe to the Podcast

COMPANY

EXPLORE

CUSTOMER CARE

LEGAL

© Copyright 2026. Danny Benjelloun. All Rights Reserved.